Manufacturer Uses Power Platform to Improve Shop Floor Productivity

Kumo helps a panel manufacturer use Power Platform to modernize an outdated paper-based process and improve shop-floor productivity.

Business Situation

How can our client use Power Platform technology to create efficiency in business processes and increase in productivity?

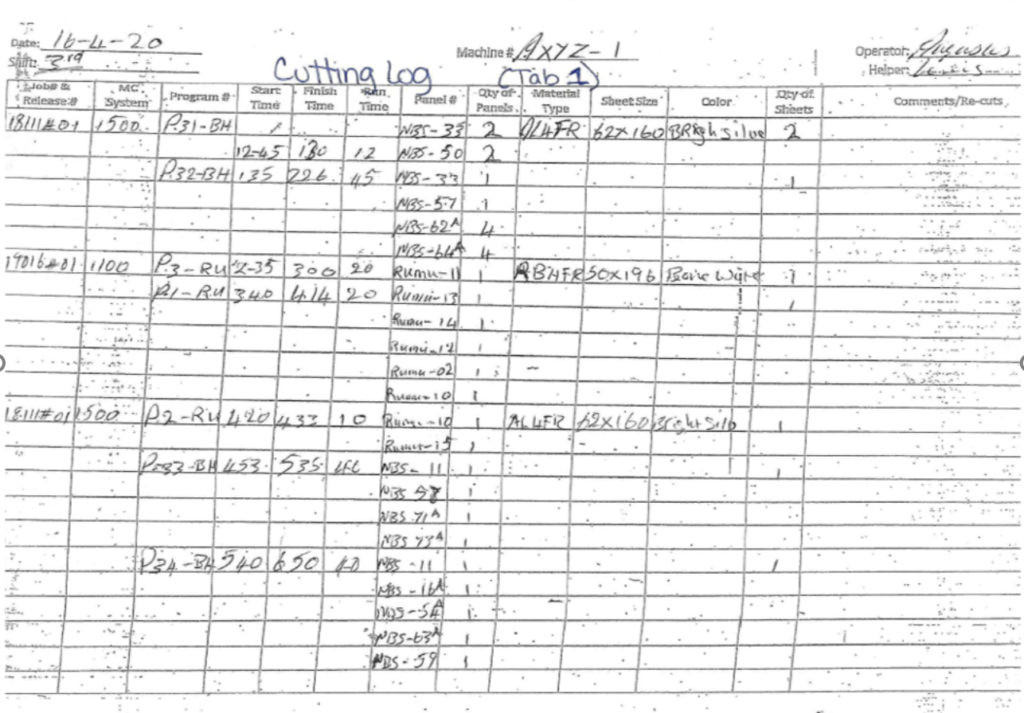

Our client, MillerClapperton, had a robust log cutting process… however, it was all logged (pun intended) by hand. Not only that, the entire process was logged and overseen by shop-floor workers. Once they finished their report, they would duplicate their efforts by manually re-creating an Excel file to represent the process.

On average, around 24 hours per week were spent manually (and repetitively) entering log data into an Excel sheet. Additionally, due to the paper-based, manual nature of data sharing, some of the report data would end up inconsistent, inaccurately entered, or entirely missing.

Key Challenges

The manufacturer was using entirely manual, paper-based processes to update all reports

The processes and reports generated were inconsistent, inaccurate, and often missing key data

Management lacked visibility into shop-floor productivity

Business Solution

Seamless integration with Microsoft AI and PowerApps

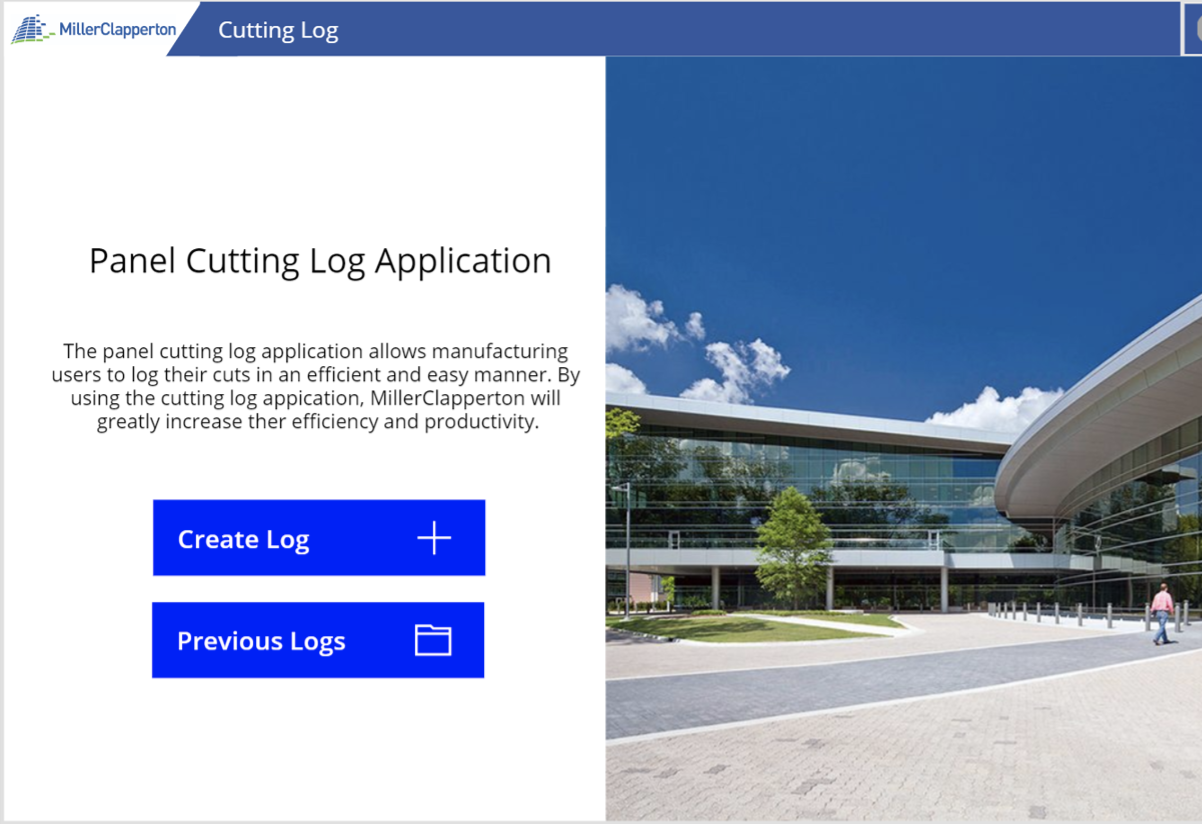

After review, Kumo Partners and MillerClapperton agreed that developing a custom PowerApp solution within the Power Platform would be the fastest route to efficiency. The team set to work building a PowerApp that allowed shop floor workers to select from pre-populated panel information and easily log their cutting data, without any manual paper logging.

The information logged on the shop floor was used to generate a PowerBI Productivity Scorecard Report that allowed MillerClapperton to improve their overall efficiency across the organization.

-

Power Platform

-

PowerBI Productivity Scorecard

-

PowerApps

-

Power Automate

Business Results

Return On Investment: 76%

Reduced Manual Data Entry by 90%

Time saved:

75 hours / month

Cost savings per employee:

$3,840/month

Technology Used: